KEY BENEFITS

Explore the high-level protective benefits of this technology

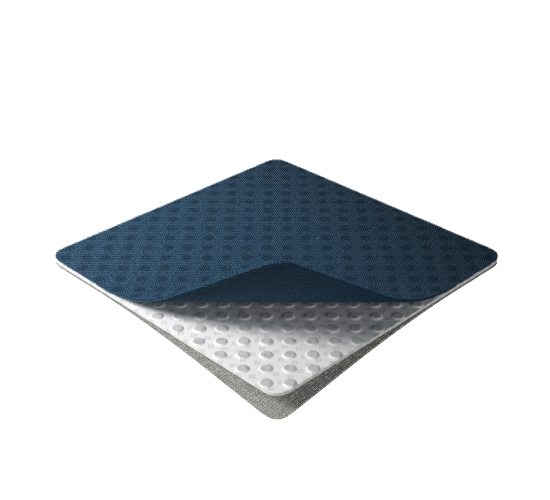

Unique PYRAD® fabric technology by GORE-TEX LABS is engineered to provide optimal protection against heat and flame by balancing flame resistance, thermal insulation and thermal stability.

PYRAD® fabric technology by GORE-TEX LABS offers lighter weight solutions compared to traditional flame retardant fabrics.

These Gore fabrics improve thermal stability and thermal insulation by enabling garments to maintain mechanical integrity following exposure to heat and flame threats.

The self-extinguishing properties provide a new level of flame resistance for personal protective equipment demonstrating a low percentage of body burn.

After exposure, the fabric will sustain a stable char that will not flake, or disintegrate, with minimal shrinkage.

PYRAD® fabric technology by GORE-TEX LABS is inherent to the fabric and is durable for the life of the product. It is not a flame retardant (FR) chemical treatment or coating, and does not wear off over time.

Extensive research and testing has been conducted to develop a portfolio of fabric innovations to deliver end-use specific functionalities and protection levels.

The technology can be universally designed with various textiles, such as nylons or polyesters, to provide FR performance while maintaining the desirable characteristics like abrasion resistance, lightweight, colorfastness and printability.